The emission reduction potential and cost-effectiveness of low-GWP refrigerants in electric vehicle air conditionings

Abstract

Electric vehicles play a crucial role in the carbon neutrality transformation of urban transportation, provided that they are powered by electricity generated from renewable (rather than fossil-based) generation sources. However, the substantial indirect emissions from electric vehicle air conditioning energy consumption and the significant direct emissions from HFCs (hydrofluorocarbons) refrigerants pose considerable challenges. In order to identify low-GWP (global warming potential) refrigerants -such as R1234yf, R744, and R290 - that can effectively minimize carbon emissions while maintaining certain cost-effectiveness, this paper establishes the relevant life-cycle analysis and life-cycle cost analysis models for electric vehicle air conditioning. The results obtained show that, in 2022, the total carbon emissions of China’s automotive air conditioning fleet were approximately 162 million tons CO2-eq. The nationwide average carbon emissions ranking of various refrigerant heat pumps is R290 < R1234yf < R744 < R134a. The Net Present Value (NPV) of the life cycle cost for R134a electric vehicle heat pump is estimated to be around 11,500 yuan. Among the three low-GWP refrigerants, the life cycle cost of R290 is significantly lower than that of R134a under nationwide average conditions, while R744 exhibits the best life cycle performance in certain cold cities/regions.

Keywords

INTRODUCTION

The electrification of vehicles, in principle, stands out as one of the most effective strategies for achieving carbon neutrality in urban transportation, which can significantly reduce reliance on fossil fuels depending on how electricity is generated, mitigate the emissions of both Green House Gases and public health relevant environmental pollutants from vehicles, and thereby lower the costs associated with environmental management and public health. Currently, almost all globally manufactured vehicles are equipped with MAC (Mobile Air Conditioning)[1]. As the largest energy-consuming facility on electric vehicles, apart from the motor, the energy conversion efficiency of the air conditioning has a profound impact on the electric vehicle’s driving range. Heat pump technology has emerged as the predominant technical solution for air conditionings in electric vehicles. However, the traditional automotive air conditioning refrigerant, R134a, exhibits a severe decline in heating performance when utilized in heat pumps as ambient temperatures decrease. In instances where the temperature falls below -5 °C, R134a automotive heat pumps typically require supplementary electric heating, resulting in a notable reduction in COP (Coefficient of Performance), and consequently generating substantial indirect carbon emissions. Furthermore, the exceedingly high GWP (Global Warming Potential) of R134a, which reaches 1,430, also points to its greenhouse effect through significant direct carbon emissions. Considering the entire life cycle of automotive air conditionings, including operation, maintenance, and disposal, refrigerant leakage is anticipated at various stages. Given China’s extensive vehicle fleet, with an estimated 0.7 kg of R134a charged in the air conditioning of a vehicle[2], the equivalent carbon content of China’s vehicles is approximately 280 million tons CO2-eq. Therefore, the adoption of low-GWP refrigerants such as HFOs, R290, or R744 in electric vehicles as replacements for R134a holds paramount significance for the urban transportation sector’s low-carbon transition.

Following China’s official announcement on September 15, 2021, of its formal accession to the Kigali Amendment to the Montreal Protocol[3], China has embarked on a historic chapter in addressing climate change and strengthening the control of HFCs and other non-carbon dioxide greenhouse gases. In order to identify environment-friendly alternatives for the widely used R134a refrigerant in automotive air conditioning, a series of attempts have been made by both the automotive industry and academia. However, due to the complex operational conditions of automotive air conditioning systems, the selection of alternative refrigerants to R134a requires careful consideration. The chosen refrigerant not only needs to have a low GWP but also must balance factors such as efficient cooling/heating capabilities, low flammability, and reasonable cost. Currently, elevated research attention has been directed towards refrigerants such as R1234yf, R744, and R290[4], and the GWP and Adp.GWP values of these refrigerants are presented in Table 1.

GWP and Adp.GWP information of refrigerants

| Refrigerants | R134a | R1234yf | R744 | R290 |

| GWP | 1,430 | < 1 | 3 | 1 |

| Adp.GWP | 1.6 | 3.3 | 0 | 0 |

The HFO-based refrigerant R1234yf, jointly developed by Honeywell and DuPont, exhibits thermal-physical properties remarkably similar to R134a[5], requiring only minor adjustments to existing systems. However, similar to R134a, R1234yf demonstrates lower heating efficiency at low temperatures. Therefore, the use of R1234yf in heat pump air conditioning requires additional supplementation with PTC (Positive Temperature Coefficient) electric heaters to meet heating demands in low-temperature conditions. Additionally, patent barriers and the higher cost of R1234yf have limited its widespread adoption[6]. R744 refrigerant, also known as CO2, is considered a promising natural low-GWP refrigerant for electric vehicle air conditioning. Wang et al. conducted experimental studies on the heating performance of a R744 automotive heat pump[7]. Their results indicated that the R744 automotive heat pump system can provide 3,600 W of heat supply at -20 °C, with a system COP as high as 3.1. However, due to the low critical temperature of CO2, the R744 automotive heat pump system must operate in a transcritical cycle, with operating pressures approximately 6-8 times higher than that of R134a systems. This requirement for high-pressure resistance also leads to high costs of components[8]. Another natural refrigerant, R290, has emerged as another primary alternative low-GWP refrigerant choice. R290, or propane, has an ODP of 0 and a GWP of 3, with operating pressures similar to R134a. Existing components meet the pressure requirements for its system operation. However, as propane is flammable and explosive, addressing refrigerant safety risks while ensuring efficiency becomes a crucial challenge[9-11]. Consequently, R1234yf, R744, and R290 face various challenges in practical applications, and the industry has yet to reach a consensus on the replacement choice for low-GWP refrigerants in EV air conditionings.

To inform the policymaking process for the substitution of low-GWP refrigerants in automotive air conditioning, researchers have conducted an analysis of the carbon emission reduction potential associated with the use of low-GWP refrigerants. For instance, Hafner et al. and Koban et al. assessed the environmental impacts of alternative refrigerants R744 and R1234yf in conventional ICEV (Internal combustion engine vehicle) air conditioning[12,13]. Additionally, some studies[14] have proposed an improved LCCP (Life Cycle Climate Performance) model for electric vehicle heat pumps based on the LCCP of ICEV automotive air conditioning, which compared and evaluated the life cycle environmental impacts of traditional refrigerants, such as R134a and R410a, with those of new refrigerants such as R744 and M2. However, the above-mentioned studies primarily conducted a LCA (Life Cycle Analysis) within the carbon accounting boundary specific to automotive air conditioning products. In reality, environmental policies - including refrigerant substitution - often require setting emission reduction targets at a national macro scale. Therefore, supplementing LCA conducted within the industry’s carbon accounting boundary for low-GWP refrigerants is crucial. In this paper, the low-GWP refrigerants R1234yf, R744, and R290 were selected as the focus, and LCA carbon emission calculations for the substitution of low-GWP refrigerants were performed separately for both the product and industry boundaries of electric vehicle air conditioning. Additionally, we included the contributions of different low-GWP refrigerants to reducing carbon emissions from R134a automotive air conditioning from the present to 2060.

Furthermore, the evolution of automotive air conditioning technology is also subject to market influences, which necessitate economic evaluation. For instance, Yue et al. conducted an economic analysis of the investment in an ORC-coupled automotive air conditioning system[15], while Wang et al. discussed the cost escalation in R744 automotive heat pumps due to the high-pressure resistance requirements of components[7]. However, there is currently a lack of reported LCCA (Life Cycle Cost Analysis) for electric vehicle air conditionings using low-GWP refrigerants. Therefore, this study establishes an LCCA model for electric vehicle air conditionings. It calculates the life cycle cost-benefit analysis of replacing traditional refrigerants with low-GWP refrigerants R1234yf, R744, and R290. Additionally, it explores the economic viability of low-temperature heat pumps specifically in cold regions of China. Ultimately, by integrating the results of both LCA and LCCA analyses, this paper provides a dual-dimensional basis that considers both the carbon emission reduction potential and respective cost-effectiveness for the selection of low-GWP refrigerants in electric vehicle air conditionings in China.

METHODS

This section initially outlines the calculation methodologies for carbon emissions from automotive air conditioning. Depending on the defined carbon accounting boundaries, the LCA of automotive air conditioning can be conducted at two distinct levels: the automotive air conditioning product level and the automotive air conditioning fleet level. For the product level, Emac is the life cycle carbon emissions of an automotive air conditioning product, which require consideration of both direct and indirect carbon emissions generated throughout its production, transportation, usage, and recycling stages, as illustrated in Figure 1. For the fleet level, the Efleet is the fleet carbon emissions of all automotive air conditioning products at a specific time point, considering the total fleet inventory, distinguishing between vehicles in various stages - newly sold, in operation, or retired. Therefore, Efleet represents the cumulative carbon emissions of all automotive air conditioning products within the fleet inventory at different life cycle stages[16]. The distinction between Emac and Efleet lies in their temporal dimensions. Emac - reflecting carbon emissions from an individual automotive air conditioning product - spans the entire life cycle duration of automotive air conditioning[17], while Efleet - representing carbon emissions from the whole automotive air conditioning fleet - is calculated at a specific time point (i.e., a particular year).

Figure 1. Life cycle of electric vehicle air conditioning, showing various life cycle stages of refrigerants and automotive air conditioning components. The yellow background on the left represents the production stage of refrigerants and MAC components. The middle section with the crimson background signifies the operational stage of MAC, which is an energy-intensive phase. The blue background on the right regarding refrigerants represents the disposal and recycling stage of MAC and refrigerants.

Given that carbon emission data for automotive air conditioning products at various lifecycle stages are an essential component of the fleet carbon emission calculation, the initial step is to calculate the life cycle carbon emissions for MAC (Equation 1).

Where EMfg is emissions during the manufacturing processes of refrigerants and automotive air conditioning components, EOT is the indirect emissions generated as the automotive air conditioning consumes energy during vehicle operation while acting as a partial load, ESO is the indirect emissions produced as the automotive air conditioning operates and consumes energy, EEOL indicates the indirect emissions generated during the disposal and recycling processes of refrigerants and automotive air conditioning systems, Eref is the direct equivalent carbon dioxide emissions resulting from refrigerant leakage from the automotive air conditioning into the atmosphere. The calculations in this section are based on our previous research[14]. The emission data for the manufacturing and disposal stages of refrigerants and air conditioning materials are detailed in Table 2. Performance test data for several refrigerants were obtained from the Jiangsu Zhongguancun Research Institute of SJTU[18-23]. The urban climate and vehicle travel data required for carbon emission calculations are primarily sourced from the China Standard Weather Database[24], the Chinese Motor Vehicle AVKT Data Report[25], and the Road Traffic Analysis Report for Chinese Urban Private Cars[26].

Manufacturing and EOL emissions data of refrigerants and materials

| Stages | Materials | Mass fraction/% | Manufacture or disposal CEF/(kg CO2/kg) |

| Manufacture | Foam plastic | 9.0% | 3.0 |

| Rubber | 4.1% | 3.1 | |

| Lubricating oil | 1.2% | 1.3 | |

| Steel | 17.0% | 2.3 | |

| Aluminum alloy | 57.6% | 1.64 | |

| Copper wire | 8.7% | 3.8 | |

| Copper alloy | 2.4% | 3.3 | |

| R134a | - | 8 | |

| R1234yf | - | 13.7 | |

| R744 | - | 0.2 | |

| Disposal | Metal | 83.5% | 0.17 |

| Foam plastic and rubber | 12.8% | 0.015 | |

| Refrigerants | - | 2.1 |

To visually depict the macroscopic impact of refrigerant replacement on emissions at the fleet level of automotive air conditioning, it is essential to conduct further calculations for the annual fleet emissions (Equation 2).

where Saley,t is the quantity of newly sold vehicles in a specific year, Stocky,t is the fleet’s total stock in that year, and Scrapy,t is the number of vehicles scrapped in that year, with “t” representing the fuel type. For the sake of convenience in computation, the annual operational emissions and refrigerant leakage emissions of the fleet are considered averages over the life of automotive air conditioning.

Following this, the economic feasibility of electric vehicle air conditioning under different refrigerant replacement options is assessed using the LCCA method. The concept of Life Cycle Cost (LCC) was first introduced by the U.S. Department of Defense in the 1960s, which represents the total cost incurred by a system throughout its entire life cycle. This concept arose because the U.S. Department of Defense found, through research, that the operational and maintenance costs of weapons typically far exceed their acquisition costs, accounting for up to 75% of the total costs.

Typically, the life cycle cost of electric vehicle air conditioning consists of two main components: the CapEx (Capital Expenditure) and the OpEx (Operating Expenditure). CapEx includes the acquisition cost associated with refrigerant and the system. The choice of refrigerant often directly impacts the system’s CapEx. For instance, a R744 system - operating at transcritical high pressures - imposes higher demands on components such as compressors and pipes, resulting in significantly elevated system costs compared to an R134a system. OpEx primarily covers the energy consumption costs incurred during the operational phase of the automotive air conditioning. It is noteworthy that different refrigerant choices can significantly affect the system’s energy efficiency, consequently influencing the energy costs throughout the life cycle. The LCCA for electric vehicle air conditioning calculates the NPV (Net Present Value) of various costs throughout the system’s lifecycle, as outlined in Equation 3.

where OpExA is the annual operating cost of EV air conditioning, the discount rate r is assumed to be 5%, and n denotes the number of years the system operates.

To demonstrate the cost-benefit of substituting low-GWP refrigerants, the ROI (Return on Investment) is defined as in Equation 4, where CapExα represents the acquisition cost of the low-GWP refrigerant system, CapExβ is the acquisition cost of the R134a system. OpExα,A and OpExβ,A are the annual operating costs of the low-GWP refrigerant system and the R134a refrigerant system, respectively.

Moreover, the IRR (Internal Rate of Return) for refrigerant replacement technology is further calculated using the IRR function in Microsoft Excel 2021. The additional cost of the low-GWP refrigerant system is defined as the initial investment, and the annual energy cost savings during the operational stage are defined as annual benefits. The discount rate at which the Net Present Value of cash flows over the life cycle equals zero represents the internal rate of return.

RESULTS

Firstly, the carbon emission reduction potential of various refrigerant replacement alternatives is calculated. Utilizing data from CSWD[24] for 31 major cities in China and incorporating them into the LCA model, the average calculated results are employed to represent the nationwide average carbon emission level for electric vehicle air conditioning. According to the literature review, the adoption of heat pump air conditioning as a replacement for PTC heating has emerged as an industry trend[20,21]. Figure 2 depicts the life cycle carbon emissions proportions of electric vehicle heat pumps employing different refrigerants. It is evident that, in the R134a refrigerant heat pump, the proportion of direct emissions caused by the refrigerant is notably high at 24.54% in the LCA. Conversely, the use of environment-friendly refrigerants such as R1234yf, R744, and R290 in heat pumps results in a significant reduction in direct emissions, with proportions all below 1%.

Figure 2. Life cycle emissions proportions of electric vehicle heat pumps using different refrigerants. The yellow portion represents direct carbon emissions caused by refrigerant leakage. Within the indirect emissions, the dark blue portion represents manufacturing carbon emissions, the light blue represents end-of-life carbon emissions, the dark gray represents carbon emissions from transporting the heat pump as a payload, and the light gray represents carbon emissions generated by the energy consumption during the operation.

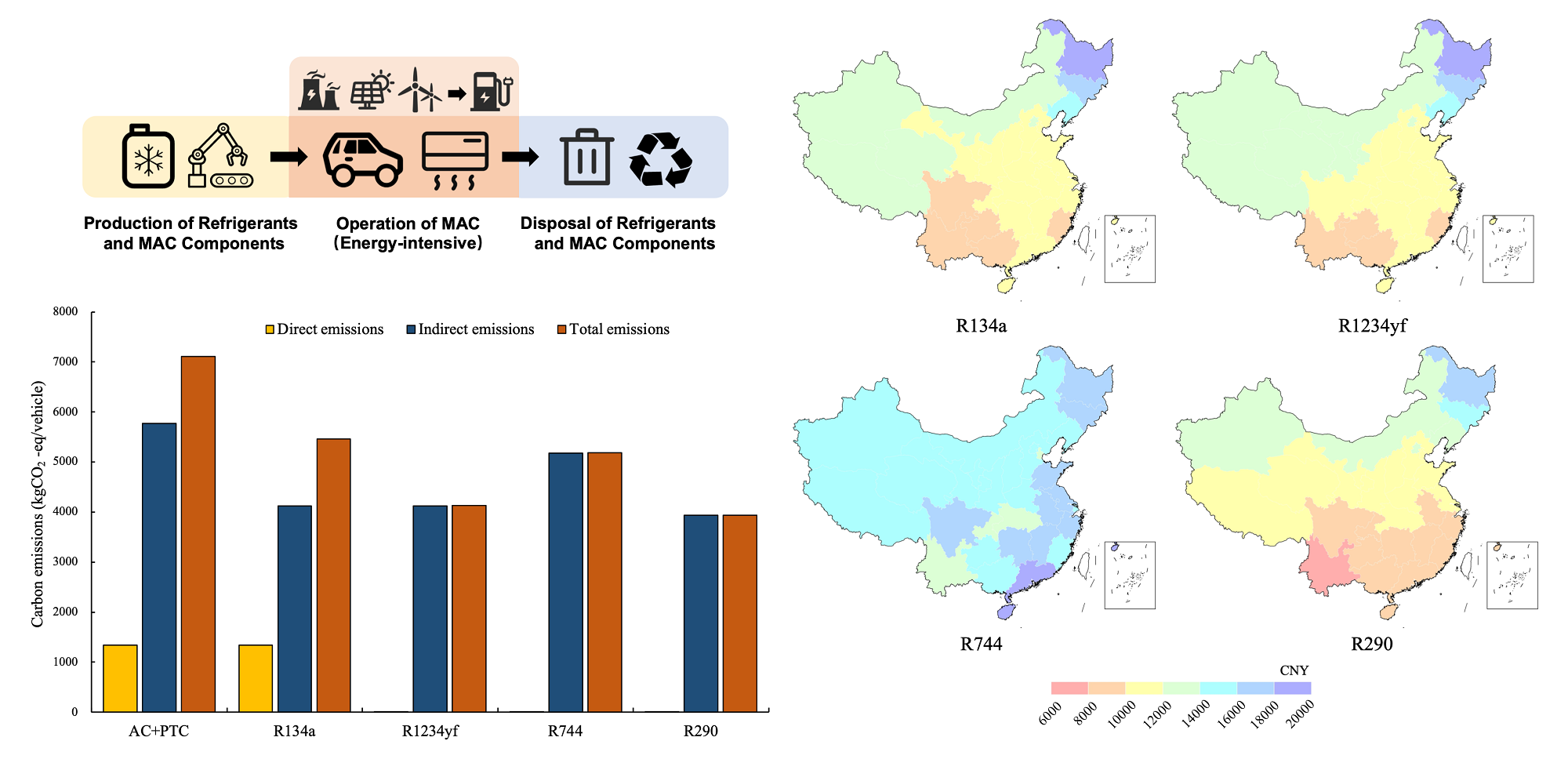

The selection of different refrigerants not only significantly affects the direct carbon emissions resulting from refrigerant leakage but also indirectly influences the operational carbon emissions generated during the operation of automotive air conditioning due to variations in system efficiency. Together, these two factors contribute to substantial variations in the life cycle carbon emissions of electric vehicle air conditioning products using different refrigerants, as depicted in Figure 3A. To highlight the emission reduction effect of utilizing heat pump technology, a comparison is made with air conditioning plus PTC heating technologies. As observed in Figure 3A, the product life cycle carbon emissions of

Figure 3. MAC life cycle carbon emissions of different refrigerant options. (A) MAC life cycle carbon emissions under nationwide average conditions. (B) MAC local life cycle carbon emissions in seven major geographic regions in China.

Quantifying the carbon emissions at the fleet level for automotive air conditioning is instrumental in providing insights for the formulation of low-carbon policies, particularly those related to the replacement of fluorinated refrigerants. The forecasted fleet carbon emissions for various refrigerant technologies in automotive air conditioning from 2022 to 2060 are presented in Figure 4. This calculation encompasses both EVs and ICEVs, with the carbon emission data for ICEV air conditioning products referencing the LCCP model[17]. The prediction of vehicle fleet size draws on the forecast by Xiang et al., which projects that China’s vehicle fleet will reach 401 million units by 2030, saturating at 645 million units by 2057[27]. The electric vehicle fleet is expected to constitute 9.6% of the total in 2025, achieving market parity with ICEVs by 2035, and reaching a fleet size of 641 million units by 2060. As depicted in Figure 4, carbon emissions in China’s automotive air conditioning industry will increase with the growth of the vehicle fleet size, peaking around 2040-2045 before gradually declining. At the industry level, the R290 technology route still exhibits the lowest fleet carbon emissions. The adoption of R290 refrigerant as a replacement for R134a is projected to result in a cumulative reduction of approximately 3.88 billion tons of carbon dioxide in the automotive air conditioning industry. The adoption of the R1234yf refrigerant would result in an estimated cumulative reduction of approximately 2.41 billion tons of carbon dioxide when replacing R134a.

Interestingly, the fleet carbon emissions of R744 refrigerant are higher than R134a. This is attributed to the high-temperature efficiency degradation of R744 air conditioning systems, leading to huge operational carbon emissions in the fleet’s air conditionings. Additionally, considering that R134a refrigerant still predominates in China’s automotive air conditioning industry, the calculated carbon emissions for the fleet in 2022 are approximately 162 million tons of carbon dioxide equivalent. This represents approximately 1.17% of the total national greenhouse gas emissions[27] and approximately 6.16% of the greenhouse gas emissions caused by national road traffic[28]. Therefore, achieving emissions reduction in the automotive air conditioning industry plays a crucial role in driving the low-carbon transformation of urban transportation.

Following the LCA of the emission reduction potential of low-GWP refrigerants, we proceeded to employ LCCA model to evaluate the cost-effectiveness of replacing low-GWP refrigerants in electric vehicle air conditioning, as depicted in Figure 5. Figure 5 illustrates significant variations in the life cycle cost of electric vehicle heat pumps with different refrigerant technology choices across various regions in China, where the values on the color-shaded slide bar refer to distinct LCC range values. This discrepancy is attributed to the vast expanse of China, spanning multiple climatic zones. The disparities in climate data among different geographical regions result in substantial variations in the operational loads of electric vehicle air conditioning, consequently leading to pronounced differences in LCCA outcomes for different cities. Therefore, it may be more reasonable for cities located in different climatic zones to adapt refrigerant replacement choices that are suitable for their specific local conditions.

Subsequently, mirroring the preceding carbon emission analysis, we have augmented the study by including the technology of AC + PTC for comparative purposes. The life cycle NPV costs of various electric vehicle air conditionings under national average conditions are depicted in Figure 6A. From Figure 6A, it is observable that while the CapEx for AC + PTC technologies is the most economical, the considerably lower energy efficiency of PTC leads to exceptionally high OpEx over the life cycle. The total life cycle NPV cost of AC + PTC technology surpasses those of R134a, R1234yf, and R290 heat pumps.

Figure 6. MAC life cycle NPV cost of different refrigerant options. (A) MAC life cycle NPV cost under nationwide average conditions. (B) MAC local life cycle NPV cost in seven major geographic regions in China.

Among heat pump air conditionings using the low-GWP refrigerants R1234yf, R744, and R290, the R290 heat pump exhibits the lowest life cycle cost, thus indicating superior cost-effectiveness under national average conditions. The R134a heat pump is currently the predominant solution for electric vehicle air conditioning, with an NPV life cycle cost of approximately 11,500 CNY. The OpEx of R1234yf heat pump air conditioning is comparable to those using R134a, but the higher refrigerant cost of R1234yf results in slightly higher CapEx than R134a. The R744 heat pump system registers the highest NPV cost, attributed to significantly higher component costs than other systems. Furthermore, the lower efficiency of the R744 system under national average conditions contributes to higher OpEx. Figure 6B illustrates the NPV of local lifecycle costs for different refrigerant electric vehicle air conditionings in seven major geographical regions in China. It is evident that the R290 heat pump has the lowest local life cycle cost in most geographical cities, making it economically favorable for nationwide promotion. Additionally, Figure 6B reveals that the economic viability of R744 heat pump air conditioning is poor in warm climate cities such as Guangzhou, Shanghai, and Chengdu. Despite its lower economic viability in warm climate regions, the R744 heat pump demonstrates the lowest local cost in the cold climate city Harbin, showcasing a superior application value in cold climate cities due to its outstanding low-temperature heating capabilities.

In regions with cold conditions - such as the north-eastern areas of China - electric vehicles suffer a significant reduction in driving range, leading to a slow adoption of EVs in these cities. Among various solutions to address the winter range issue, low-temperature heat pump technology stands out as one of the most effective. However, the current high cost of CO2 low-temperature heat pumps hampers the development of the technology. Therefore, we have analyzed the economic feasibility of applying CO2 heat pump air conditioning in cold cities and examined the impact of potential cost reductions with the maturity of its industry chain. The R134a heat pump is used as a reference in the calculations. The results obtained demonstrate the economic advantages of using CO2 vehicle heat pump air conditioning instead of R134a heat pump air conditioning in some cold Chinese cities. Under the current conditions of an immature industry chain and the associated technology costs, the ROI for CO2 systems compared to R134a has reached 172%, with an IRR of approximately 24% over the entire life cycle. Assuming a 10% cost reduction in CO2 heat pump expenses once the industry chain matures, the ROI could soar to 315%, and the IRR could increase to 40%. Therefore, despite the higher initial purchase cost, the outstanding economic performance of CO2 low-temperature heat pumps over the entire life cycle appears compelling enough to attract consumers in cold climate cities. Furthermore, the potential for cost reduction as the industry matures will enhance the future application prospects of this technology.

DISCUSSION

Electric vehicles play a crucial role in the low-carbon transformation of urban transportation, depending on the generation source of the electricity to power them. However, the substantial indirect emissions from air conditioning energy consumption and the significant direct emissions from refrigerants pose considerable challenges. In order to identify low-GWP refrigerants that can effectively minimize emissions while maintaining certain cost-effectiveness, this paper establishes a LCA model for electric vehicle air conditioning within both the product and fleet carbon accounting boundaries. Then, we investigate the emission reduction potential of using low-GWP refrigerants such as R1234yf, R744, and R290 as alternatives to R134a. Subsequently, a consumer-oriented LCCA model for electric vehicle air conditioning is developed to calculate the NPV life cycle cost and analyze the investment benefits after refrigerant replacement.

However, this study also has some limitations. For instance, the LCA model used in this study primarily focuses on analyzing the impact of different low-GWP refrigerant options on the carbon emissions of electric vehicle air conditioning. Nevertheless, it is important to note that, unlike the indirect emissions generated by the fuel consumption of air conditioning in traditional ICEV, the indirect emissions of EV air conditioning are tied to the electricity consumption of vehicle batteries. Therefore, the CEF (Carbon Emission Factor) of the power grid will significantly influence the carbon emissions of electric vehicle air conditioning. Considering the continuous increase in the installed capacity of green energy sources in China, which is leading to a decreasing trend of CEF over time, the predicted carbon emissions of the MAC fleet in Figure 4 of this paper should also be appropriately adjusted. Hence, it is more reasonable to supplement the prediction of the power generation technology trajectory in China’s electricity system, thereby obtaining a more accurate calculation of GHG emissions within the carbon accounting boundary for automotive air conditioning fleet predictions.

CONCLUSION

The primary conclusions of this paper are as follows:

1. At the carbon accounting boundary of electric vehicle air conditioning products, the use of heat pump technology can achieve a carbon reduction of 23% to 45% compared to PTC heating. Among several heat pump air conditioning systems that use low-GWP refrigerants as alternatives to R134a, the R290 system exhibits the lowest life cycle carbon emissions, approximately 3,939.7 kg CO2-eq. The ranking of LCA results for electric vehicle air conditioning under different refrigerant options is R290 < R1234yf < R744 < R134a < AC + PTC.

2. At the carbon accounting boundary of the automotive air conditioning fleet, the carbon emissions of China’s automotive air conditioning fleet in 2022 amount to approximately 162 million tons of CO2-eq, accounting for about 1.17% of the national carbon emissions and 6.16% of the carbon emissions caused by road transportation. Emissions reduction in the automotive air conditioning industry is of significant importance for national urban carbon neutrality. The future carbon emissions of the automotive air conditioning fleet will increase with the growth of the vehicle fleet until around 2040-2045, when it is expected to decline gradually. At the fleet level, the LCA of the R290 route has the comparatively lowest carbon emissions, and replacing R134a with R290 is estimated to achieve a cumulative emission reduction of approximately 388 million tons of CO2-eq.

3. The LCCA results for electric vehicle air conditioning using different refrigerants indicate that the AC + PTC technology, although exhibiting the comparatively lowest CapEx, incurs an extremely high OpEx and thus has poor economic viability. While the R744 heat pump exhibits strong low-temperature heating capabilities, the predominance of temperate and subtropical climates in China may limit its economic viability in most cities. Among the refrigerant options studied in this paper, the current industry-standard R134a heat pump has a life cycle NPV cost of approximately 11,500 CNY, with the R290 system exhibiting the comparatively lowest NPV cost under national average conditions. Combining the analyses of LCA and LCCA, this paper suggests that the R290 heat pump has an excellent carbon emission reduction potential and also cost-effectiveness in most Chinese cities, making it a promising choice for refrigerant replacement in electric vehicle air conditioning.

4. Ideally, selecting low-GWP refrigerants and air conditioning technologies suitable for local conditions is a suggested rational approach. For instance, the economic benefits of low-temperature heat pumps are well demonstrated in cold climates. In some cold cities such as Harbin, the ROI of the R744 system relative to the R134a has already reached 172%, with an IRR of approximately 24% over the life cycle. Hence, the R744 heat pump - with its outstanding capabilities in low-temperature heating and favorable life cycle economic benefits - holds substantial appeal for consumer groups in northern Chinese cities. Moreover, considering that the carbon emissions of the R744 heat pump are lower than those of R134a in cold regions, the development of this technology is poised to expedite the low-carbon transformation of transportation in certain cold climate cities of China.

5. Enhanced communication and collaboration between the academic and industrial sectors in the refrigeration and automotive industries are recommended to effectively address the challenges of replacing HFC refrigerants and reducing GHG emissions in automotive air conditionings. Furthermore, we suggest that relevant national authorities regulate automotive air conditioning systems as an integrated whole, systematically considering both direct and indirect emissions from the entire life-cycle of air conditioning. This involves establishing comprehensive carbon emission standards and limits for automotive air conditionings, incorporating air conditioning testing into emission testing protocols. Additionally, there should be increased support for research in electricity vehicle air conditionings and low-GWP refrigerant technologies. This support aims to encourage automotive manufacturers to take the lead in adopting these technologies, thereby accelerating the industrialization process of low-GWP refrigerants.

DECLARATIONS

Authors’ contributions

Made substantial contributions to the conception and design of the study and performed data analysis and interpretation: Li A, Yu B, Zhang Y, Ouyang H, Guo Z

Performed data acquisition, as well as providing administrative, technical, and material support: Shi J,

Availability of data and materials

Not applicable.

Financial support and sponsorship

None.

Conflicts of interest

All authors declared that there are no conflicts of interest.

Ethical approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Copyright

© The Author(s) 2024.

REFERENCES

1. Direk M, Hosoz M, Yigit KS, et al. Experimental performance of an R134a automobile heat pump system coupled to the passenger compartment. In: world renewable energy congress - Sweden, 8-13 May 2011, Linköping, Sweden. Available from: https://www.researchgate.net/publication/269125615_Experimental_Performance_of_an_R134a_Automobile_Heat_Pump_System_Coupled_to_the_Passenger_Compartment [Last accessed on 20 Feb 2024].

2. Hu ZL, Zhang C, Yang F, Fu L. Development trends of thermal management technology for electric vehicles based on vehicle energy management. Autom Abstr 2019;5:1. Available from: https://g3mv.com/thesis/detail/1992705 [Last accessed on 20 Feb 2024].

3. Wu Q, Ma D, Lin XY, Peng D, Dou GY. International experience in greenhouse gas control of air conditioners for vehicles and its enlightenments. 2022. Available from: http://www.ceec.cn/zyzx/sjhjzz/zzlm/tszs/202302/P020230214520032932758.pdf [Last accessed on 20 Feb 2024].

4. Wang C, Cao F, Li M, Yin X, Song Y, He Y. Research status and future development of thermalmanagement system for new energy vehicles underthe background of carbon neutrality. Chin Sci Bull 2021;66:4112-28.

5. Golzari S, Kasaeian A, Daviran S, Mahian O, Wongwises S, Sahin AZ. Second law analysis of an automotive air conditioning system using HFO-1234yf, an environmentally friendly refrigerantAnalyse selon le second principe d'un système de conditionnement d'air automobile fonctionnant au HFO-1234yf, frigorigène respectueux de l'environnement. Int J Refrig 2017;73:134-43.

6. Liu YS, Li WY, Zhang L, Shi JY, Chen JP. Performance of automotive ultra-low temperature economized vapor injection heat pump air conditioning using r1234yf refrigerant. J Shanghai Jiao Tong Univ 2020;54:1108-16.

7. Wang D, Yu B, Hu J, Chen L, Shi J, Chen J. Heating performance characteristics of CO2 heat pump system for electrical vehicle in a cold climate. Caractéristiques des performances de chauffage d’un système de pompe à chaleur au CO2 pour un véhicule électrique dans un climat froid. Int J Refrig 2018;85:27-41.

8. Baek C, Heo J, Jung J, Cho H, Kim Y. Optimal control of the gas-cooler pressure of a CO2 heat pump using EEV opening and outdoor fan speed in the cooling mode. Régulation optimale de la pression du refroidisseur de gaz d'une pompe à chaleur au CO2 à l'aide de l'ouverture du détendeur électronique et de la vitesse du ventilateur externe, en mode refroidissement. Int J Refrig 2013;36:1276-84.

9. Ghodbane M. An investigation of R152a and hydrocarbon refrigerants in mobile air conditioning. In: international congress and exposition, SAE technical paper 1999-01-0874. 1999.

10. Ghodbane M, Craig TD, Baker JA. Demonstration of an energy-efficient secondary loop HFC-152a mobile air conditioning system. 2007. Available from: https://www.researchgate.net/profile/Timothy-Craig-3/publication/237297660_Demonstration_of_an_Energy-Efficient_Secondary_Loop_HFC152a_Mobile_Air_Conditioning_System/links/5554b2c808ae980ca60acf5a/Demonstration-of-an-Energy-Efficient-Secondary-Loop-HFC152a-Mobile-Air-Conditioning-System.pdf [Last accessed on 20 Feb 2024].

11. Li G, Eisele M, Lee H, Hwang Y, Radermacher R. Experimental investigation of energy and exergy performance of secondary loop automotive air-conditioning systems using low-GWP (global warming potential) refrigerants. Energy 2014;68:819-31.

12. Hafner A, Neksa P. Global environmental consequences of introducing R-744 (CO2) mobile air conditioning. In: 7th IIR gustav lorentzen conference on natural working fluids. 2006. Available from: https://archive.r744.com/files/pdf_233.pdf [Last accessed on 20 Feb 2024].

13. Koban M. HFO-1234yf low GWP refrigerant LCCP analysis 2009-01-0179. In: SAE world congress & exhibition, SAE technical paper, 2009. Available from: https://www.sae.org/publications/technical-papers/content/2009-01-0179/ [Last accessed on 20 Feb 2024].

14. Yu B, Long J, Wang D, Ouyang H, Shi J, Chen J. Life cycle climate performance (LCCP) evaluation model for electric vehicle heat pumps and emission reduction analysis of low-GWP refrigerants. Chin Sci Bull 2023;68:841-52.

15. Yue C, You F, Huang Y. Thermal and economic analysis of an energy system of an ORC coupled with vehicle air conditioning. Analyse thermique et économique du système énergétique d'un cycle organique de Rankine (ORC) couplé avec un système de conditionnement d'air de véhicule. Int J Refrig 2016;64:152-67.

16. China Automotive Technology Research Center. Research report on China’s low-carbon action plan for automobiles 2021[EB/OL]. Available from: https://www.digitalelite.cn/h-nd-1515.html?fromColId=30 [Last accessed on 20 Feb 2024].

17. Papasavva S, Hill WR, Andersen SO. GREEN-MAC-LCCP: a tool for assessing the life cycle climate performance of MAC systems. Environ Sci Technol 2010;44:7666-72.

18. Zhang Z, Li W, Zhang C, Chen J. Climate control loads prediction of electric vehicles. Appl Therm Eng 2017;110:1183-8.

19. Li W, Liu R, Liu Y, Wang D, Shi J, Chen J. Performance evaluation of R1234yf heat pump system for an electric vehicle in cold climate. Évaluation de la performance d’un système de pompe à chaleur au R1234yf pour un véhicule électrique en climat froid. Int J Refrig 2020;115:117-25.

20. Yu B, Ouyang H, Shi J, Guo Z, Chen J. Experimental evaluation of cycle performance for new-developed refrigerants in the electric vehicle heat pump systems. Évaluation expérimentale de la performance du cycle pour les frigorigènes nouvellement mis au point dans les systèmes de pompe à chaleur des véhicules électriques. Int J Refrig 2021;129:118-27.

21. Wang D, Yu B, Li W, Shi J, Chen J. Heating performance evaluation of a CO2 heat pump system for an electrical vehicle at cold ambient temperatures. Appl Therm Eng 2018;142:656-64.

22. Yu B, Yang J, Wang D, Shi J, Guo Z, Chen J. Experimental energetic analysis of CO2/R41 blends in automobile air-conditioning and heat pump systems. Appl Energy 2019;239:1142-53.

23. Yu B, Ouyang H, Shi J, Liu W, Chen J. Evaluation of low-GWP and mildly flammable mixtures as new alternatives for R410A in air-conditioning and heat pump system. Évaluation de mélanges à faible PRP et légèrement inflammables comme nouvelles alternatives au R410A dans les systèmes de conditionnement d’air et de pompes à chaleur. Int J Refrig 2021;121:95-104.

24. China Meteorological Bureau. China standard weather data for analyzing building thermal conditions. Beijing: China Building Industry Publishing House. 2005.

25. Xiaoxiong fuel consumption. 2017 annual mileage report of the car owners in Xiaoxiong fuel consumption. 2018. Available from: https://zhuanlan.zhihu.com/p/43119608 [Last accessed on 20 Feb 2024].

26. AutoNavi. 2018|Q1 traffic analysis report of major cities in China. Available from: http://cn-hangzhou.oss-pub.aliyun-inc.com/download-report/download/quarterly_report/18Q1/Traffic%20Analysis%20Report%202018Q1.pdf [Last accessed on 20 Feb 2024].

27. Xiang XY, Zhao XC, Jiang PN, et al. Scenario analysis of hydrofluorocarbons emission reduction in China's mobile air-conditioning sector. Adv Clim Chang Res 2022;13:578-86.

28. Peter T, Lew F. Transport energy and CO2: moving towards sustainability. Paris: International Energy Agency. 2009. Available from: https://www.oecd.org/publications/transport-energy-and-co2-moving-towards-sustainability-9789264073173-en.htm [Last accessed on 20 Feb 2024].

Cite This Article

Export citation file: BibTeX | RIS

OAE Style

Li A, Yu B, Zhang Y, Ouyang H, Guo Z, Shi J, Chen J. The emission reduction potential and cost-effectiveness of low-GWP refrigerants in electric vehicle air conditionings. Carbon Footprints 2024;3:6. http://dx.doi.org/10.20517/cf.2023.54

AMA Style

Li A, Yu B, Zhang Y, Ouyang H, Guo Z, Shi J, Chen J. The emission reduction potential and cost-effectiveness of low-GWP refrigerants in electric vehicle air conditionings. Carbon Footprints. 2024; 3(2): 6. http://dx.doi.org/10.20517/cf.2023.54

Chicago/Turabian Style

Li, Anran, Binbin Yu, Yingjing Zhang, Hongsheng Ouyang, Zhikai Guo, Junye Shi, Jiangping Chen. 2024. "The emission reduction potential and cost-effectiveness of low-GWP refrigerants in electric vehicle air conditionings" Carbon Footprints. 3, no.2: 6. http://dx.doi.org/10.20517/cf.2023.54

ACS Style

Li, A.; Yu B.; Zhang Y.; Ouyang H.; Guo Z.; Shi J.; Chen J. The emission reduction potential and cost-effectiveness of low-GWP refrigerants in electric vehicle air conditionings. Carbon. Footprints. 2024, 3, 6. http://dx.doi.org/10.20517/cf.2023.54

About This Article

Special Issue

Copyright

Data & Comments

Data

Cite This Article 4 clicks

Cite This Article 4 clicks

Comments

Comments must be written in English. Spam, offensive content, impersonation, and private information will not be permitted. If any comment is reported and identified as inappropriate content by OAE staff, the comment will be removed without notice. If you have any queries or need any help, please contact us at support@oaepublish.com.